QuadLN_S Firmware

QuadLN_S Version 3.4 Update Package

Current production QuadLN_S Version 3.4 firmware including user manual. Version 3 has the most recently added features including support for up to 16 servos or stall motors, servo refresh, aspect-controlled turnouts, oscillate mode, center-align, etc. See the included ReadMe file for more info. JMRI 5.10 is required to access the latest features in firmware version 3.4. JMRI 5.8 supports all QuadLN_S firmware features though firmware version 3.3. Do not attempt to install firmware version 3.4 unless you are running JMRI 5.8 or later.

QuadLN_S Version 3.2 Update Package

QuadLN_S Version 3.2.4 firmware including manuals. Version 3.2.4 is very stable. See the included ReadMe file for more info.

QuadLN_S Version 2.0.7 Update Package

QuadLN_S Version 2.0.7 firmware including manuals covering V2 features for all QuadLN_S family products. See the included ReadMe file for more info.

JMRI

JMRI version 5.10 has been released, and it supports all QuadLN_S firmware versions up to 3.4. Please update your JMRI version to 5.10 to support the QuadLN_S current production version 3.4 firmware.

Manuals

QuadLN_S Manual Version 3.4 Firmware

QuadLN_S Manual Version 3.3 Firmware

QuadLN_S Getting Started v3.3 Firmware

QuadLN_S Manual Version 3.2 Firmware

QuadLN_S Getting Started v3.2 Firmware

QuadLN_S Manual Version 2 Firmware

Remote Align Board Quick Start

Instruction Sheets

Pushbutton with LED Ring Light

Signal Connector Interface Board

Linear Switch Machine Throw Wire Changeout

Mounting Drawings

QuadLN_S Mounting Drawings (c) 2025 N3IX Engineering

Dimensioned mounting drawings for the QuadLN_S and all add-on boards. The zip file includes 1:1 scale drawings for Letter and A4 size paper in both English and Metric units.

Mounting Plate

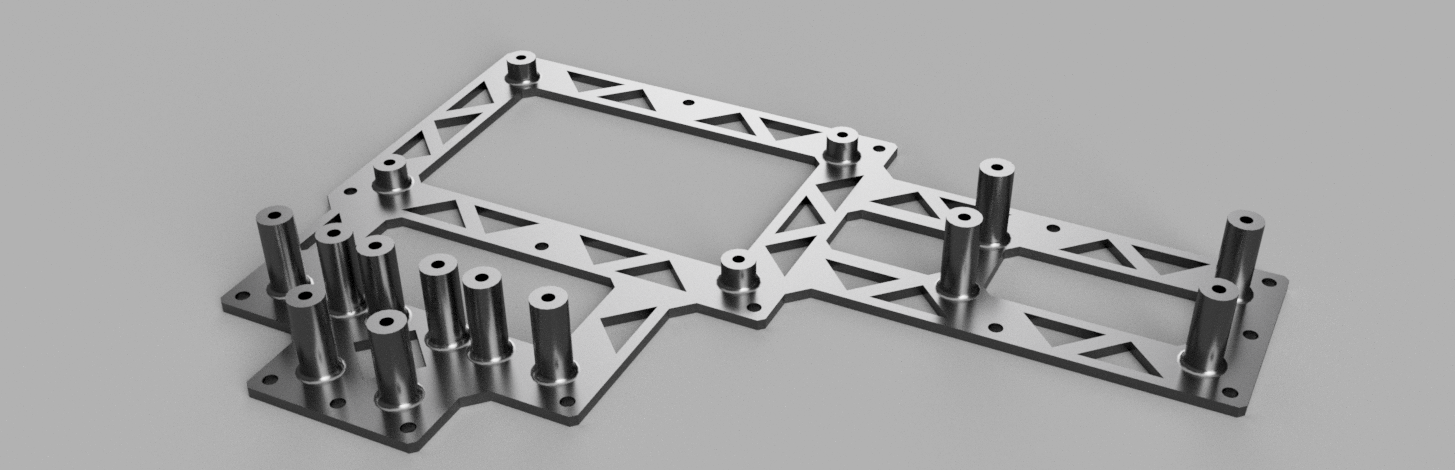

QuadLN_S Mounting Plate stl file (c) 2022 N3IX Engineering

A QuadLN_S mounting plate design for 3D printing. The mounting plate has built-in standoffs for a QuadLN_S and any combination of Detector, Signaling and Driver add-on boards. Use 1/4″ or 3/8″ long #4 self-tapping screws to secure the boards to the mounting plate, then attach the mounting plate to a flat surface using appropriate length #4 screws as required.

I typically print the mounting plates using PLA with 25% infill. Printing takes about 3 hours on my Vyper. The board mounting hole size has been tweaked to make it easy for me to start #4 screws without pre-drilling. Depending on your printer and filament you may need to clean out the holes using a 3/16″ or 7/32″ bit, or alternatively use a small amount of “Hole Horizontal Expansion” in your slicer, to make threading the screws easier and lessen the risk of breaking a standoff.

If you aren’t installing a Driver Board in the AUX IO Port, you can just snip off the standoff closest to the Remote Align Connector to make access to the connector easier.

QuadLN_S Mounting Plate for TVD boards stl file (c) 2022 N3IX Engineering

The QuadLN_S mounting plate design as above, but adjusted for the board sizes and hole locations of the legacy QuadLN_S, Signal and Detector boards that were produced by Tam Valley Depot.

Drill Guides

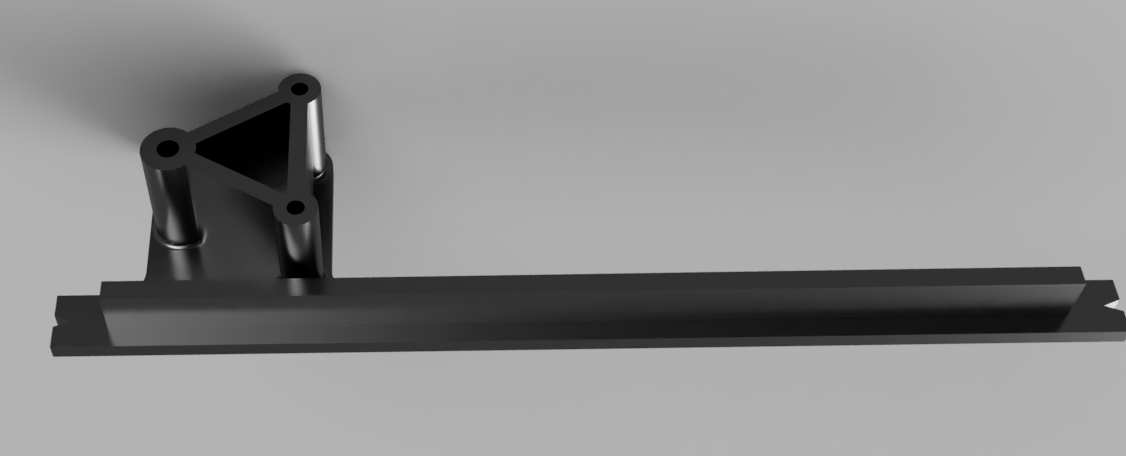

3-D Printed N Scale Atlas Code 55 Drill Guides and more

Drill templates you can print for use with the Linear Switch Machines and Atlas Code 55 N Scale Turnouts. To download the printer files click the link to go to my layout 3D Printing page.

Tips and App Notes

Yard Track Selection Via Single Button Press For 6 Track Yard

Guide to configuring the Cascade feature for easy alignment of a 6 track yard ladder to the desired yard body track via a single button press. Also covers setting up LED indicators to display the currently selected yard body track. All done using just one QuadLN_S.

Yard Track Selection Via Single Button Press For 10 Track Yard

Guide to configuring the Cascade feature for easy alignment of a 10 track yard ladder to the desired yard body track via a single button press. Also covers setting up LED indicators to display the currently selected yard body track. Uses 2 QuadLN_S boards (some of the second board is available for other uses) plus a Signal Board.

Example JMRI Jython Script to Interrogate QuadLN_S boards one at a time

At startup JMRI attempts to determine the state of all LocoNet Turnouts and Sensors using a process called Stationary Interrogation. On large layouts many LocoNet devices may respond to each Interrogation message, resulting in message collisions, long delays and possible lost information. QuadLN_S firmware version 3.1.4 and later can be configured to support direct interrogation, where only one QuadLN_S board responds to each status request. This approach provides for reliable initialization on large layouts. The sample script individually interrogates all QuadLN_S boards in the roster between a specified starting board address and a specified ending board address.

DigiKeijs DR5000 settings for reliable LocoNet communication

Settings that users have found improves the DR5000 communications with the QuadLN_S and other LocoNet devices.

User Support Groups

Tam-Valley-Products@groups.io is the forum for QuadLN_S questions and discussion.

jmriusers@groups.io is the place for all things JMRI.